Novel concept for patient-specific immobilization using generative design and additive manufacturing

PO-1635

Abstract

Novel concept for patient-specific immobilization using generative design and additive manufacturing

Authors: Bertrand Dewit1, Tom Depuydt2,1

1UZ Leuven, Radiation Oncology, Leuven, Belgium; 2KU Leuven, Oncology, 3000, Belgium

Show Affiliations

Hide Affiliations

Purpose or Objective

Thermoplastic masks are currently the

standard in RT immobilization. These can however be uncomfortable due to

shrinkage, induce claustrophobia and can limit beam angle selection in

treatment plans. We therefore propose a novel concept for more comfortable

patient-specific and plan-optimized head and neck immobilization devices using

the full potential of additive manufacturing (AM) and Computer-Aided Design

(CAD).

Material and Methods

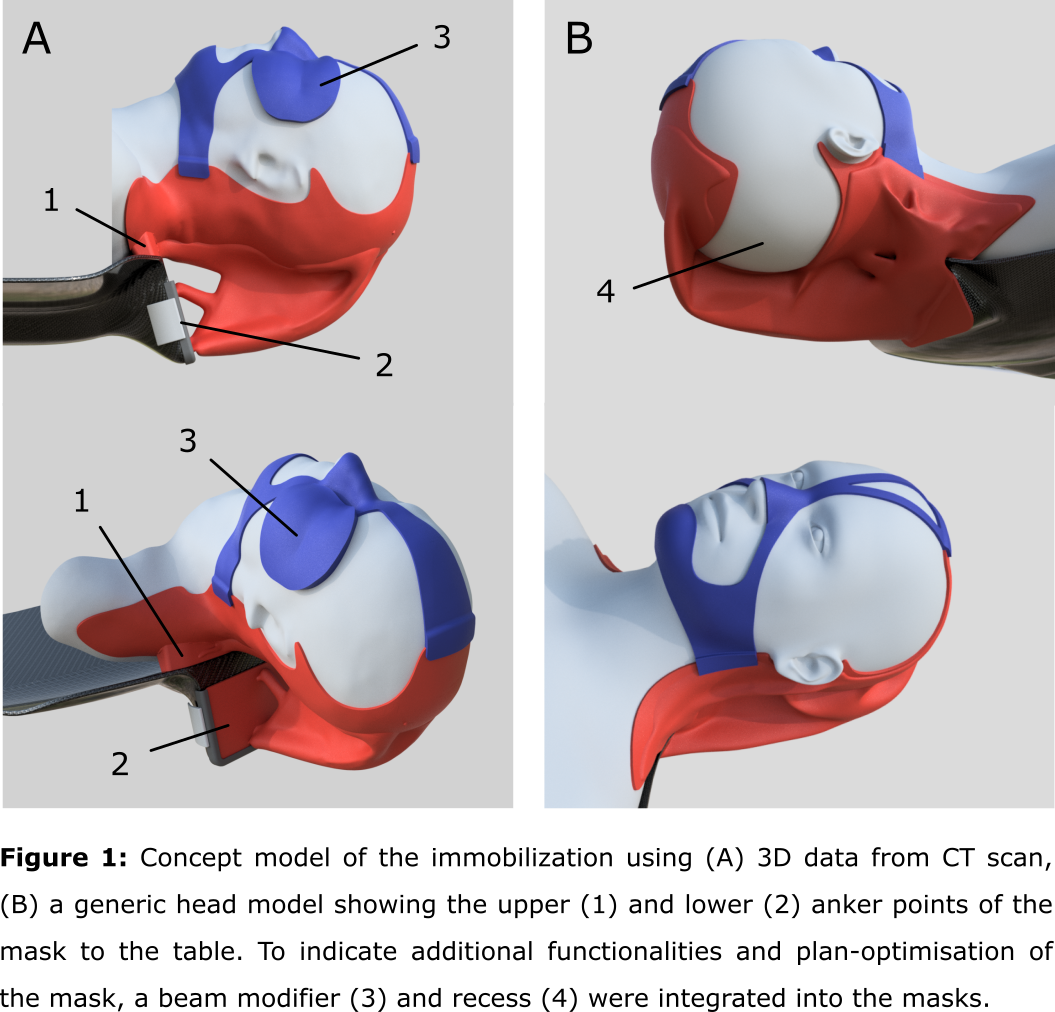

To design

the immobilization, CT data of a head and neck patient was retrospectively

collected. The body contour was segmented from the head up to the shoulders in

Mimics® (Materialise) and exported as a 3D mesh. All subsequent CAD was

performed in fusion360® (Autodesk). First, the body mesh was converted into a

solid modelling boundary representation and positioned on a concept model of

the envisioned treatment table, including two attachment sites for the immobilization.

Next, a two-part mask was designed around the patient’s body. The lower shell

includes the shoulders and a cranial stop and the upper part the nose bridge

and the chin (figure 1). Using AI assisted generative design (GD) the

connection between the lower shell and the table attachments were generated

using a downward load case of 35 N to represent an adult human head and HP PA12

nylon as the printing material of choice. Regions to be avoided such as a

treatment machine bore or nozzle can be taken into account in the GD process. A

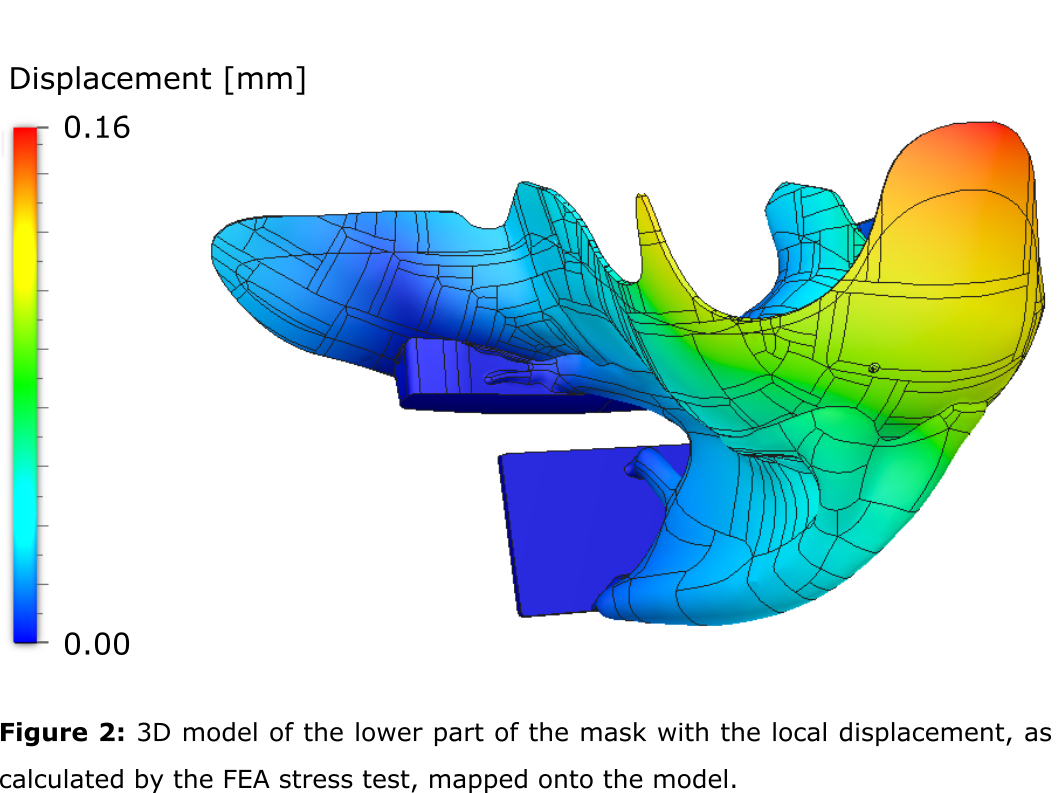

Finite Element Analysis (FEA) static stress test was performed to calculate the

factor of safety (FoS) and expected displacement.

Results

The proposed workflow allowed for the creation of a

patient-specific open face mask starting from CT data. We were able to integrate

additional functionalities to the immobilization structure such as a beam

modifier (bolus/range shifter) and in-vivo dosimetry which can ensure accurate

placement of these devices with respect to the patient anatomy. The

immobilization device could also be customized to the treatment plan, by avoiding

the beam having to pass through material or structural edges which can disturb

the intended dose distribution in the patient (figure 1). This can ultimately

allow more flexibility in the beam angle selection, potentially resulting in an

improved treatment plan quality. The static stress test indicated a realized FoS

of 9.6, indicating that further optimisation of the support could reduce the

use of material and production cost given that a safety factor of 2-3 should

suffice. A maximal displacement of 0.16 mm was indicated (figure 2).

Conclusion

The

realised FoS and maximal displacement given by the FEA indicates that our novel

immobilization using GD and AM is a viable concept. We therefore conclude that the

proposed workflow shows to be a promising new concept for patient immobilization.

Future work would include investigating the use of surface scanning and extensive

testing of the stability, reproducibility and comfortability of the immobilization

devices using phantoms and eventually patients.