Development of deformable 3D anthropomorphic dosimetry systems for proton therapy

PO-1572

Abstract

Development of deformable 3D anthropomorphic dosimetry systems for proton therapy

Authors: Simon Jensen1, Tobias Erichsen2, Morten Jensen1, Peter Balling3, Jørgen Petersen4, Per Poulsen1, Ludvig Muren1

1Aarhus University, Department of Clinical Medicine, Aarhus, Denmark; 2Aarhus University, Deparment of Engineering, Aarhus, Denmark; 3Aarhus University, Department of Physics and Astronomy, Aarhus, Denmark; 4Aarhus University Hospital, Department of Medical Physics, Aarhus, Denmark

Show Affiliations

Hide Affiliations

Purpose or Objective

Pencil

beam scanning (PBS) proton therapy offers individualized conformal dose

distributions. However, intra-fractional motion in the abdomen and thorax is a

major challenge and can severely degrade the dose distribution.

Building up to a clinical protocol for liver tumours in our proton centre, we

are developing an anthropomorphic dosimetry phantom, containing clinically

realistic deformable three-dimensional (3D) dosimetry inserts, onto which complex

deformations can be applied.

The aim of this study was to establish a method for producing high precision

anthropomorphic 3D dosimeters to fit into this phantom.

Material and Methods

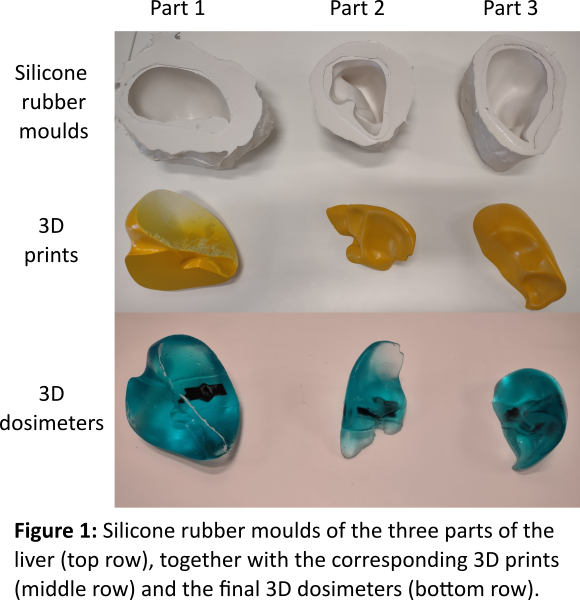

The

dosimeter moulds were created using a 3D printed organ as a negative. The shape

of an adult-size liver was divided into three parts to minimize the optical

pathlength through the individual dosimeter parts and 3D printed using a polylactic

acid filament. The parts were sanded down, coated with a layer of primer, and

spray-painted to provide a smooth surface (Figure 1).

A casting basin was made from sculpting clay and filled with silicone moulding

rubber. The 3D print was suspended in the basin and the moulding rubber was

left to cure for 24 hours.

The 3D dosimeters were prepared using transparent silicone kit, chloroform, and

the radiation-sensitive component leucomalachite green, poured into the moulds and

cured for 72 hours prior to irradiation. A specially designed nut was suspended

in the dosimeter during curing for later attachment to the read-out system.

The dosimeters were x-ray computed tomography (CT) scanned and imported to the

treatment planning system (TPS). The treatment plan consisted of six conventional

6 MV photon fields (15 mm x 15 mm) evenly spaced on a 180-degree arc with a

prescribed dose of 5 Gy normalized to 100% in target maximum. A four-degrees-of-freedom

couch correction was performed using a cone-beam CT.

The optical density (OD) of the dosimeters was read-out pre- and

post-irradiation using an optical CT scanner with 1000 projections and reconstructed

using the ordered-subsets-convex total-variation method.

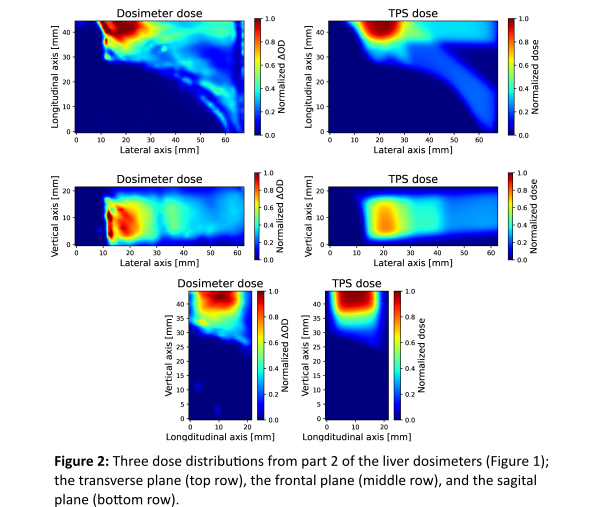

The TPS dose distribution was compared to the experimental dose distributions

using a 3%/3 mm 3D gamma analysis including only voxels above 10% of the

maximum TPS dose.

Results

The

silicone rubber moulds were successfully made with great detail reproducing all

visible filament lines from the 3D prints and had the advantage that it was

easy to separate the 3D dosimeters from the moulds compared to rigid moulds. Most

of the dose was delivered in just one of the liver-dosimeter parts (Figure 2) and

here we achieved a gamma pass rate of 87%. The main challenges in the optical

read-out were the dosimeter edges along with the signal-to-noise ratio.

Conclusion

The

described method successfully produced reusable anthropomorphic moulds for 3D

dosimeters. Furthermore, the liver irradiation showed a fair correlation

between the TPS calculation and experimental measurements and indicates its

suitability for future proton irradiations.