Dosimetric characterization of PLA 3D printed boluses for external beam radiotherapy

PO-1546

Abstract

Dosimetric characterization of PLA 3D printed boluses for external beam radiotherapy

Authors: Matteo Pepa1, Simone Giovanni Gugliandolo2, Floriana Pansini3, Andrea Vavassori1, Maria Giulia Vincini1, Mattia Zaffaroni1, Daniela Alterio1, Shankar Rajendran4, Shabarish Purushothaman Pillai4, Stefania Volpe5, Giulia Marvaso5, Giulia Corrao5, Federica Cattani1, Bianca Maria Colosimo6, Barbara Alicja Jereczek-Fossa5

1IEO European Institute of Oncology IRCCS, Division of Radiation Oncology, Milan, Italy; 2Politecnico di Milano, Department of Mechanical Engineering; Department of Chemistry, Materials and Chemical Engineering, Milan, Italy; 3IEO European Institute of Oncology IRCCS, Unit of Medical Physics, Milan, Italy; 4Politecnico di Milano, Department of Mechanical Engineering, Milan, Italy; 5University of Milan; IEO European Institute of Oncology IRCCS, Department of Oncology and Hemato-Oncology; Division of Radiation Oncology, Milan, Italy; 6Politecnico di Milano, Department of Mechanical Engineering , Milan, Italy

Show Affiliations

Hide Affiliations

Purpose or Objective

Radiotherapy boluses are able to shift the build-up region and are

mandatory to treat superficial lesions. The aim of this study is to produce 3D-printed

boluses and evaluate how different process parameters (infill pattern and

density, materials, etc.) influence their dosimetric behaviour with respect to a

conventional bolus.

Material and Methods

A SHAREBOT 42 3D printer (Sharebot, Nibionno, Italy)

was used to print boluses, of simple geometry and made of polylactic acid (PLA),

to test different combinations of infill densities, printing patterns, and batches

of the same material. Duplicates were produced for all printed boluses, which

were subsequently irradiated with a 6MV clinical photon beam from Vero® accelerator

system (BrainLAB, Feldkirchen, Germany) and a prescription dose of 2Gy to the

surface, using a Gafchromic® EBT3 film dosimeter placed between RW3

slabs phantom. Measurement films were scanned from 24 to 48 h after irradiation

using a desktop flat-bed transmission Epson Expression Scanner 10000 XL and analysed

with “film QA-pro” software to compare the maximum dose location for each bolus

and for the conventional one. Statistical tests on dose and depth data were

carried out to evaluate the influence of each process parameter on the outcome.

Results

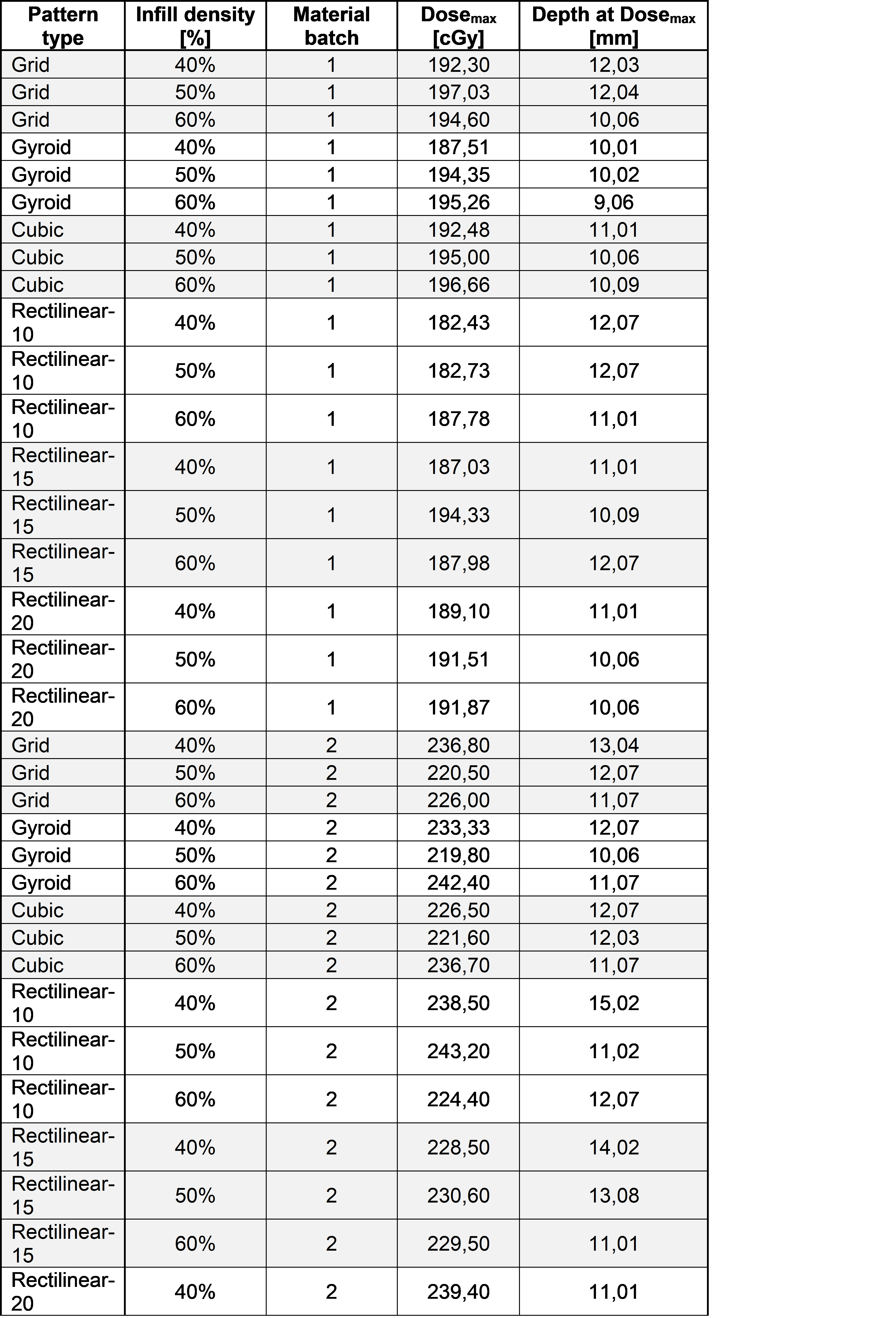

The conventional bolus showed a maximum dose of 195.39

cGy located at (10.5±0.3) mm. Regarding the 3D-printed boluses results are

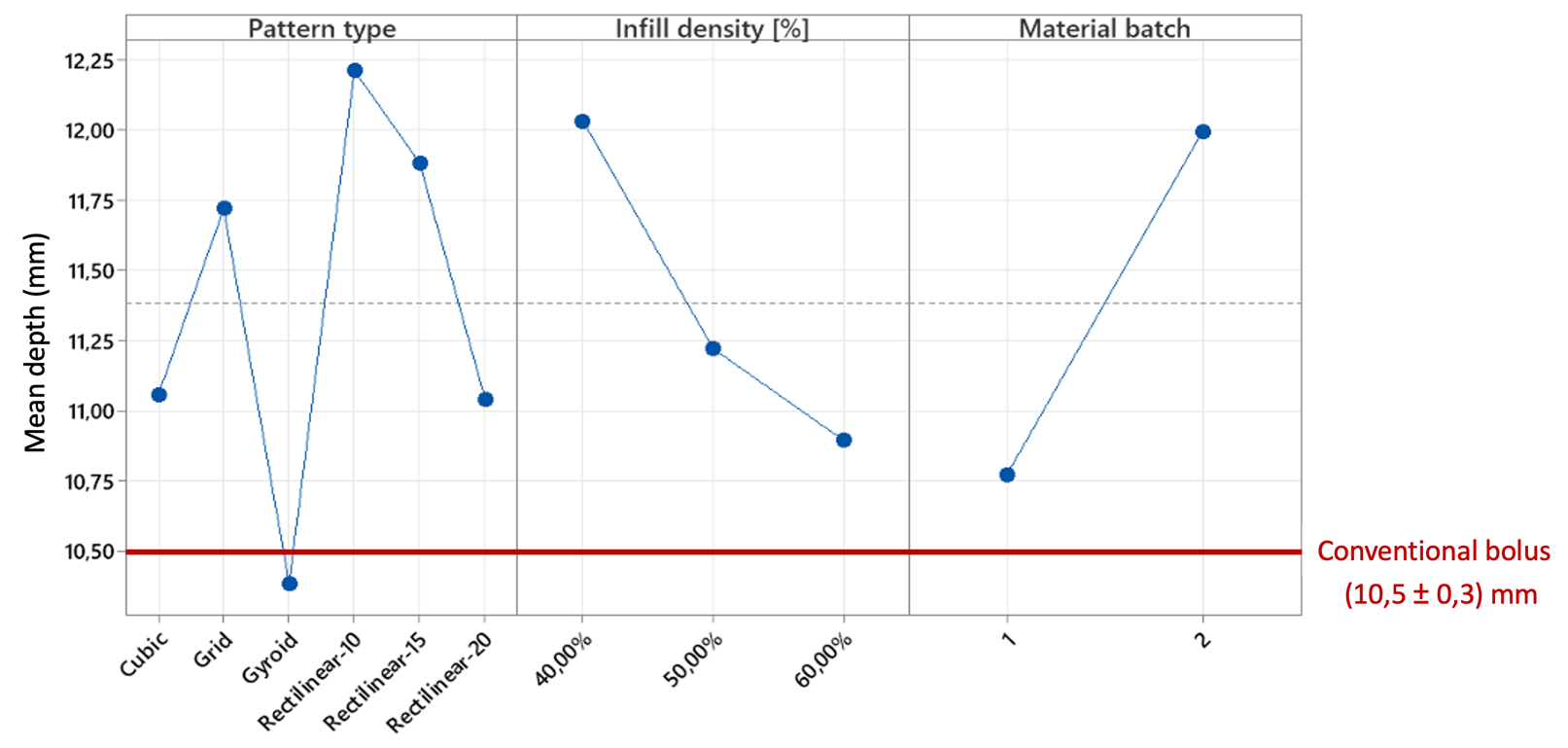

showed in Table 1. A preliminary statistical analysis showed that

infill pattern type and density and batch of materials affected the bolus

behavior (fig.1). However, in general, values comparable to those of the

conventional bolus were obtained with 3D-printed samples. The infill density,

as expected, had an important effect on shifting the depth at which the maximum

dose was located.

Table 1. Values

of maximum doses and the depth at which they were recorded in the dosimeter are

here reported. Four different pattern types were chosen: grid, gyroid, cubic

and rectilinear. The latter was designed with 3 different orientation degrees.

Figure 1.

Effect of pattern type, infill density, and material batch on Dosemax

location (mm).

Conclusion

A preliminary dosimetric characterization

of PLA 3D-printed boluses was done and encouraging results were found for the

use of 3D printed boluses in such a field. Optimization of parameters to obtain

optimal values of infill pattern and density should be investigated to better

correlate the entity of the maximum dose shift and to validate a substitute to the

conventional bolus. Future perspectives include to test different materials and

free-form shapes which can better adapt to the patient’s anatomy.