Improvements of Elekta Fletcher type applicator in brachytherapy using 3D printing technology

PO-2139

Abstract

Improvements of Elekta Fletcher type applicator in brachytherapy using 3D printing technology

Authors: Andrei Tšižik1, Nikolai Saveljev1, Martin Tigasson2

1The North Estonia Medical Centre, Radiotherapy, Tallinn, Estonia; 2The North Estonia Medical Centre, Medical Technology Division, Tallinn, Estonia

Show Affiliations

Hide Affiliations

Purpose or Objective

The aim of this research is to improve clinical target volume coverage for the Fletcher type applicator from Elekta by making 3D printing add-on.

Material and Methods

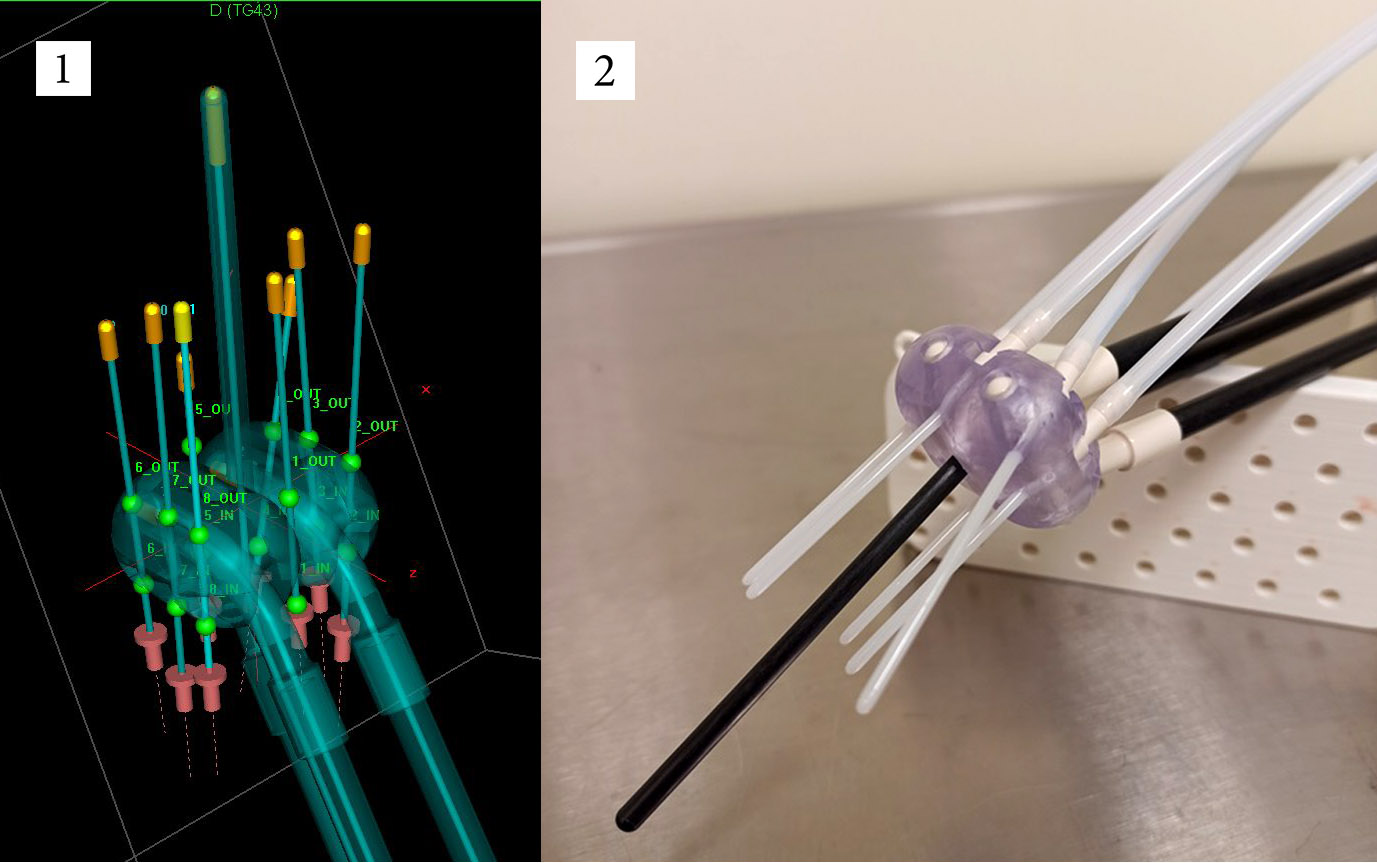

The 15 mm ovoid library model was exported from the Oncentra 4.6.0 planning system as an xml file. Blender 2.93.0 design software was used to modify a virtual 3D model. The ovoids were joined together in the coronal plane with the halves of the straight sides, leaving a tandem opening in the center for further fixation of the resulting monoovoid. This solution provides an opportunity to install additional needles in the direction of the bladder and rectum, which is not possible with the geometry of the standard applicator. The resulting model was imported back into the Oncentra planning system (1) to create a pretreatment plan, i.e. determine new interstitial needle locations, transfer them to a three-dimensional model, and draw them in Blender software.

Biomed Clear Resin (Formlabs) was used in the production of monoovoid. Parts printed with BioMed Clear Resin are compatible with common sterilization methods.

To verify the geometric properties of the monoovoid, the finished monovoid (2) was assembled with other parts of the applicator and scanned with CT using CT markers on the needles. According to the CT markers in the Oncentra system, the locations of the needles were reconstructed and the same reference points used in the modeling stage were built.

VeriSoft 8.0 software was used to compare the dose distributions of the original and 3D printed applicators.

1. 3D applicator with needles in Oncentra planning system

2. Fletcher applicator with 3D add-on and needles

Results

Biomed Clear Resin was used in the production of monoovoid, which is biocompatible and suitable for invasive procedures.

The maximum difference between the dimensions of the 3D model and the 3D printed addition is 0.4 ± 0.05 mm and 0.1°.

The stability of the material was checked in the STERRAD sterilization system operating on hydrogen peroxide. The largest volume reduction was 0.2 mm.

For dose distribution DTA/DD (distance to agreement/dose difference) 2mm/5% criteria and the passing percentage of 90% were used. Two- and three-dimensional dose distribution analyzes showed accuracies of 98.5% and 94.7% respectively. The experiment showed that the planned and real needle locations coincided, with differences in simulated dose distributions ranging from 1.5 to 5.3%.

Based on a specific clinical case, 3D add-on could increase the overlap of the target volume with the treatment dose by 18%.

Conclusion

3D printing makes it possible to adjust the size and shape of the individual treatment applicator and the angles of the interstitial needles to achieve a better dose distribution, i.e. to improve the quality of treatment.